Table of Contents

- Introduction and Historical Evolution

- The Meaning of the Circular Economy

- H&M Plating’s Role in the Circular Economy

- Case Study: Collaboration with Shell in Oil & Gas

- Adapting to Industry Needs: Manufacturing & Construction

- Commitment to Continuous Improvement and Sustainability

- Employee Training and Expertise

- Diverse Applications of H&M Plating Services

- Primary Markets Served by H&M Plating

- Looking Ahead: H&M Plating’s Vision for the Future

- FAQs

- Conclusion

Introduction and Historical Evolution

Established in 1971, H&M Plating embarked on a journey to provide unparalleled reconditioning and protective coating processes to a myriad of industries. From the petrochemical sector to marine, from hydraulic and pump industries to metal and manufacturing, H&M Plating’s expertise in electroplated hard industrial chrome, sulfamate nickel, thermal spray, and a suite of other processes has been sought after.

Over the decades, the company has witnessed impressive growth, expanding from its initial foundation to a sprawling six-building complex spanning 65,000 sq. ft. The acquisition of Mirror Industries in 2016 added another 40,000 sq. ft., and the subsequent purchase of Schumacher Company and Dixie Electro Plating in 2019 introduced an additional 75,000 sq. ft., now operating under the name Schumacher-Dixie, LLC.

At the heart of H&M Plating’s success is a dedicated team with unparalleled experience. Their commitment is unwavering — delivering wear-resistant protection, competitive pricing, and professional service that’s unmatched in the industry. With operations running 24/7, they ensure timely deliveries, boasting a standard turnaround varying from 1-2 days up to 2 weeks depending on the parts. Their reach isn’t just limited to the Gulf Coast; they proudly serve clients throughout North and South Americas.

The Meaning of the Circular Economy

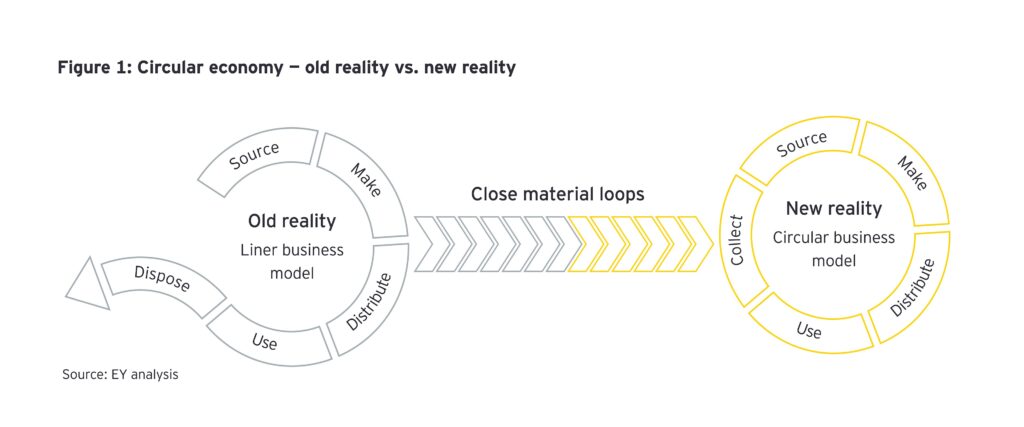

The term “circular economy” might appear as modern jargon, but its essence is deeply transformative. When one delves into the circular economy’s meaning, they uncover a concept that challenges our traditional linear system of “take, make, dispose”. In its place, the circular economy advocates for a systemic shift where products and materials are continually recycled, reused, and regenerated, minimizing waste and maximizing utility.

Historically, industries have operated on a linear model: extracting resources, producing goods, and then discarding them. While this approach fueled swift industrialization and economic growth, it also led to environmental degradation, resource scarcity, and waste accumulation.

The circular economy, through its innovative model, seeks to address these challenges. It’s not just about recycling; it’s a holistic approach where resources are kept in use for as long as possible, extracting maximum value during their lifecycle and then recovering and regenerating products and materials post-use. This model serves as an ideal circular economy example of how businesses can be both profitable and sustainable.

H&M Plating’s Role in the Circular Economy

H&M Plating’s commitment to the principles of the circular economy is both explicit and unwavering. They stand out as a prime example of a company that seamlessly integrates sustainability with business excellence. At the core of this commitment is their dedication to the repair, re-coating, and reconditioning of equipment.

In many industries, the wear and tear on machinery and equipment can be substantial. When these vital components degrade, the traditional approach has often been to replace them, leading to increased resource extraction, production, and waste. This linear approach not only strains our planet’s finite resources but also results in significant economic costs. H&M Plating’s approach directly challenges this model. By refurbishing and rejuvenating worn-out or damaged equipment, they not only prevent unnecessary waste but also extend the lifespan of the equipment, ensuring that the energy, materials, and labor that went into its initial production continue to provide value.

This approach has multiple benefits. First, it reduces the need for new resource extraction, thus conserving valuable materials and reducing environmental impact. Second, by giving equipment a second life, H&M Plating helps companies save costs that would otherwise be spent on producing or purchasing new machinery. This not only translates to economic savings but also reduces the carbon footprint associated with the production of new equipment.

Furthermore, H&M Plating’s practices are in line with the broader objectives of the circular economy. They collaborate with specialized recycling partners to ensure that any waste from their processes is managed responsibly, further minimizing their environmental impact. Their work showcases tangible examples of circular economy products in action, from the reconditioned equipment that returns to service in industries to the waste materials that find new life in other applications.

By placing sustainability at the heart of their operations, H&M Plating demonstrates that the principles of the circular economy are not just theoretical constructs but can be applied practically, with tangible benefits for both businesses and the environment.

Case Study: Collaboration with Exxon in Oil & Gas

H&M Plating’s expertise shines brightly in their collaboration with Exxon, especially when adapting circular economy principles to the intricate requirements of the oil & gas sector. Shell, intending to run hydrochloric acid (HCl) through their equipment, presented a distinctive material challenge. HCl, known for its aggressive corrosive properties, requires robust and resistant materials to ensure equipment longevity and safety.

Chrome, though durable in many contexts, isn’t ideally suited for prolonged exposure to hydrochloric acid. Recognizing this, H&M Plating, with their vast reservoir of knowledge, recommended HVOF process — a tungsten carbide material renowned for its resilience against HCl. This wasn’t just a decision about material compatibility; it reflected H&M Plating’s commitment to offering solutions optimized for specific industrial applications, underscoring their role in promoting the circular economy in oil & gas.

Adapting to Industry Needs: Manufacturing & Construction

Whether it’s in manufacturing or construction, H&M Plating tailors its services based on the specific equipment, environment, and materials being processed. Their experience across diverse sectors equips them to offer solutions that address unique challenges, championing the principles of the circular economy in manufacturing and construction alike.

Commitment to Continuous Improvement and Sustainability

H&M Plating’s ethos revolves around continuous improvement and sustainability. Feedback-driven practices and commitment to recycling and waste management make them a beacon for circular economy and sustainability.

Employee Training and Expertise

Behind H&M Plating’s exemplary services lies a team of skilled professionals. Continuous training ensures that the team remains at the forefront of industry knowledge and sustainable practices.

Diverse Applications of H&M Plating Services

H&M Plating’s versatility is evident in the wide array of applications they cater to. From hydraulic shafts, pump internals, and impellers to specialized equipment like blowout preventer internals and extrusion equipment. They also offer reconditioning for molds, tools, dies, machine parts, and even valve reconditioning. This vast range of applications underscores H&M Plating’s comprehensive expertise and ability to adapt to diverse industry needs.

Primary Markets Served by H&M Plating

H&M Plating’s impact resonates across various industries. Their primary markets include:

- Oil & Gas Industries

- Petrochemical Industries

- Pump Industries

- Turbine Industries

- Compressor Industries

- Hydraulic Industries

Their vast clientele in these sectors is a testament to their reliability, expertise, and the value they bring to these industries. Catering to such a wide spectrum of markets, H&M Plating ensures that its services are tailored to meet the specific needs and challenges of each industry, reinforcing their commitment to excellence and sustainability.

Looking Ahead: H&M Plating’s Vision for the Future

Innovation and sustainability are deeply embedded in H&M Plating’s DNA. They envision further advancements in coating materials and processes, all while championing the principles of the circular economy. As industries evolve, so does H&M Plating, ensuring that they’re always at the cutting edge of both technology and sustainability.

FAQs

- Q: What’s the circular economy meaning?

- A: It’s an economic model promoting the reuse, recycle, and regeneration of resources, emphasizing sustainability and innovation.

- Q: Can you provide a circular economy example?

- A: H&M Plating’s practice of repairing and re-chroming equipment, reducing waste and resource extraction.

- Q: How does H&M Plating ensure product longevity in the oil & gas sector?

- A: By recommending materials like tungsten carbide that withstand the corrosive effects of substances like hydrochloric acid.

- Q: How is H&M Plating contributing to waste management in the circular economy?

- A: H&M Plating emphasizes repairing and re-chroming equipment to extend its lifespan and collaborates with specialized recycling partners to manage waste, showcasing a commitment to reducing environmental impact.

- Q: What role does H&M Plating play in promoting the circular economy in manufacturing and construction?

- A: They offer tailored solutions based on the specific equipment, environment, and materials, ensuring resources remain in use for as long as possible and reducing the need for new resource extraction.

Conclusion

H&M Plating exemplifies the confluence of industry expertise and sustainability. Their robust approach to the circular economy not only sets them apart as leaders but also serves as a beacon for other industries. By intertwining operational excellence with sustainable practices, they’re paving the way for a future where economic growth and environmental stewardship coexist harmoniously.