Table of Contents

- Introduction: The World of Twin-Screw Compressors

- How Twin-Screw Compressors Work

- The Evolution: A Glimpse into History

- The Need for Durability: Challenges Faced by Twin-Screw Compressors

- Benefits of Chrome Plating for Twin-Screw Compressors

- Environmental Impact and The Role of Chrome Plating in the Circular Economy

- Real-World Impact: Case Studies

- Looking Ahead: Navigating Market Trends

- Conclusion: H&M Plating’s Commitment to Excellence

- FAQ

1. Introduction: The World of Twin-Screw Compressors

Image by Sunil Kr Sarangi

Twin-screw compressors are more than just machines; they are the heartbeat of numerous industries, from refrigeration to power generation. These compressors, with their intricate design involving two intermeshing helical screws, have revolutionized the way we think about gas compression. Their synchronized movement ensures not just a consistent gas flow, but a testament to human engineering prowess. Their importance in modern industrial applications cannot be overstated, making them a focal point for innovations and advancements.

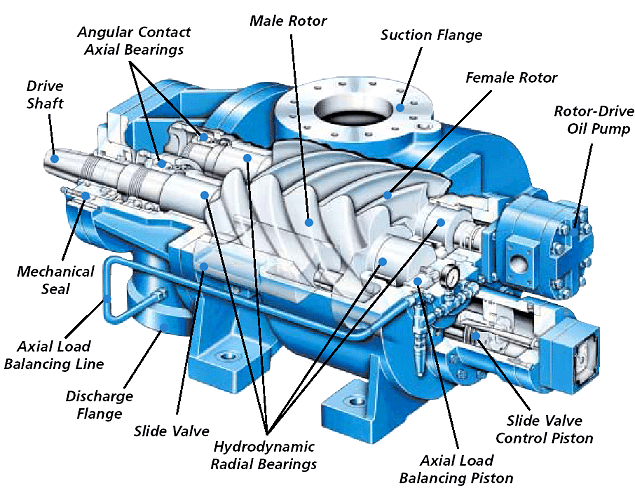

2. How Twin-Screw Compressors Work

At the heart of a twin-screw compressor lie two helical rotors or screws. These screws are designed to intermesh perfectly without touching each other. When the compressor is in operation, these screws rotate in opposite directions. As they turn, the space between them decreases, compressing the gas trapped between the screw threads and the compressor housing. This mechanism allows for a continuous intake, compression, and discharge of gas, ensuring a smooth and uninterrupted flow. The precision in design and manufacturing of these screws is paramount, as even the slightest misalignment can lead to decreased efficiency or potential damage. The continuous compression process, as opposed to the piston-like action in other compressors, results in smoother operation with fewer vibrations, making twin-screw compressors ideal for applications requiring steady and reliable compression.

3. The Evolution: A Glimpse into History

The journey of twin-screw compressors from their inception to their current state is a tale of innovation and adaptation. Born in the early 20th century, these compressors have witnessed the ebb and flow of industrial demands. As industries burgeoned, so did the need for more resilient and efficient compressors. Chrome plating, with its shimmering aesthetics, soon found a deeper purpose. Beyond its beauty, it offered a protective embrace to these compressors, ensuring they could withstand the rigors of industrial demands.

4. The Need for Durability: Challenges Faced by Twin-Screw Compressors

Twin-screw compressors often operate in challenging environments, ranging from the high-humidity settings of refrigeration systems to the dusty and gritty surroundings of construction sites, and even the high-temperature conditions of power generation plants. These varied environments expose the compressors to a myriad of external factors that can accelerate wear and tear.

Chrome plating emerges as a crucial solution in this context. This intricate process transforms ordinary compressor parts into resilient, long-lasting components. After a meticulous cleaning process, parts are bathed in an electrolytic solution rich with chromium ions. An electric dance then ensues, with current causing chromium to adhere to the component, forming a protective, gleaming layer. This isn’t just any layer; it’s a guardian against wear, corrosion, and friction, especially vital given the challenging environments these compressors often find themselves in.

5. Benefits of Chrome Plating for Twin-Screw Compressors

The world of twin-screw compressors is one of precision, efficiency, and relentless operation. These compressors, due to their continuous mode of operation, are subjected to constant friction, wear, and potential corrosion. The benefits of chrome plating in this context are manifold and deeply rooted in the empirical findings of numerous experimental studies:

- Reduced Friction: One of the primary challenges faced by twin-screw compressors is the friction between its moving parts. Friction not only reduces the efficiency of the compressor but also accelerates wear. Chrome plating provides a smoother surface, which significantly reduces frictional forces. This reduction in friction leads to smoother operation, reduced heat generation, and increased overall efficiency.

- Enhanced Wear Resistance: The continuous operation of twin-screw compressors means that wear and tear are inevitable. However, chrome plating offers a hard and resilient surface that can withstand the constant movement of parts, thereby dramatically reducing wear rates. This ensures that the compressor parts retain their shape and function for a longer period, leading to reduced maintenance intervals and costs.

- Corrosion Protection: Twin-screw compressors often operate in environments where they are exposed to moisture, chemicals, or other corrosive agents. Chrome plating forms a protective barrier that shields the underlying metal from these corrosive elements, ensuring the longevity and consistent performance of the compressor.

- Thermal Stability: Chrome plating has a high melting point and excellent thermal stability. This means that in high-temperature operations, chrome-plated parts are less likely to deform or degrade, ensuring the compressor’s consistent performance even under extreme conditions.

- Improved Sealing Efficiency: The precision and smoothness offered by chrome plating can enhance the sealing efficiency between the screws, leading to better compression and reduced leakage. This ensures that the compressor operates at its peak efficiency, delivering optimal performance.

- Economic Benefits: While the initial investment in chrome plating might seem significant, the long-term economic benefits are substantial. The extended lifespan of parts, reduced maintenance costs, and increased operational efficiency lead to significant cost savings over the compressor’s operational life.

In light of the experimental studies related to twin-screw compressors, it becomes evident that chrome plating is not just a luxury or an aesthetic choice. It’s a strategic decision that enhances the compressor’s performance, durability, and efficiency, ensuring that industries can rely on their compressors for consistent and uninterrupted operation.

6. Environmental Impact and The Role of Chrome Plating in the Circular Economy

In our rapidly evolving world, environmental responsibility isn’t just a choice; it’s a mandate. Traditional chrome plating methods, while effective, posed environmental challenges. But with adversity comes innovation. Modern chrome plating techniques are a testament to human ingenuity, prioritizing sustainability without compromising on quality. Waste reduction, water conservation, and the use of environmentally-friendly materials are now at the heart of the chrome plating process.

H&M Plating, always at the industry’s vanguard, exemplifies this green revolution. Their commitment to recycling hexavalent chromium and their relentless pursuit of eco-friendly practices set them apart. But their vision goes beyond just sustainable practices; it aligns with the broader ethos of the circular economy. By rejuvenating worn-out machinery and extending product lifespans, chrome plating reduces the voracious demand for new products, championing a future where sustainability and industry walk hand in hand.

7. Real-World Impact: Case Studies

The transformative power of chrome plating isn’t just theoretical; it’s palpable and can be witnessed across industries. Companies globally, armed with chrome-plated twin-screw compressors, have stories to tell. ABC Industries, for instance, narrates a tale of resurgence, where chrome-plated components breathed new life into their compressors, leading to a 30% surge in lifespan. Such stories aren’t anomalies; they are testimonials to the undeniable prowess of chrome plating.

8. Looking Ahead: Navigating Market Trends

The horizon of the compressor industry is aglow with promise. As sectors like manufacturing, HVAC, and energy burgeon, the demand for resilient and efficient compressors is set to soar. In this evolving tapestry, chrome plating emerges as the thread that binds durability with efficiency. As we navigate these market trends, the symbiotic relationship between twin-screw compressors and chrome plating becomes even more pronounced, heralding a future where performance meets longevity.

9. Conclusion: H&M Plating’s Commitment to Excellence

In the realm of chrome plating, H&M Plating stands as a beacon of excellence. With years of experience under their belt, they have consistently showcased their expertise in delivering top-tier chrome plating solutions tailored for industrial equipment. Their commitment goes beyond just providing a service; it’s about ensuring that each piece of machinery they treat stands the test of time, operates efficiently, and does so in an environmentally responsible manner.

H&M Plating’s dedication to sustainability is evident in their practices. By recycling hexavalent chromium and continuously innovating to reduce their environmental footprint, they not only set standards for themselves but also pave the way for the industry. Their approach to chrome plating is holistic, considering both the immediate benefits to the machinery and the long-term impact on the environment.

Their reputation as industry leaders is well-earned. Through a combination of technical prowess, customer-centric services, and a forward-thinking approach to sustainability, H&M Plating has solidified its position at the forefront of the chrome plating industry. As industries evolve and the demand for durable, efficient, and eco-friendly machinery grows, H&M Plating’s role as champions of both quality and sustainability becomes even more pivotal.

10. FAQ

Q: What are twin-screw compressors primarily used for? A: They are versatile machines used predominantly in refrigeration, industrial manufacturing, gas processing plants, and power generation.

Q: Why is chrome plating the go-to solution for compressors? A: Chrome plating offers unmatched wear resistance, corrosion protection, friction reduction, and aesthetic enhancement, making it ideal for the demanding environments in which compressors operate.

Q: Are there environmental concerns with chrome plating? A: While traditional methods using hexavalent chromium raised environmental concerns, modern techniques with trivalent chromium are more environmentally friendly.

Q: How does chrome plating impact the lifespan of a twin-screw compressor? A: Chrome plating significantly boosts the lifespan of twin-screw compressors by offering unparalleled protection against wear, corrosion, and friction.